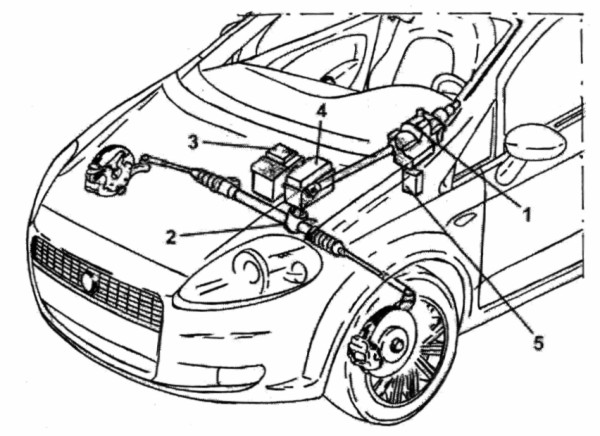

The principle of operation of the booster. In this system, the steering shaft consists of two parts connected by a flexible joint. The bottom of the shaft goes through: by the actuator control mechanism and is mounted in it. A gear wheel is mounted at the end of the lower part of the shaft, meshed with the gear driving the globoid worm of the steering mechanism. The worm meshes with the roller mounted on the transverse shaft, at the end of which there is a lever, coupled with a hydraulic cylinder. The pump which maintains the oil operating pressure in the drive system is jointly with the generator. When turning the steering wheel, the corresponding valves in the steering mechanism are opened and oil is supplied to the hydraulic cylinder, which increases the pressure on the longitudinal bar. As already mentioned, the booster only then works, when the driver turns the steering wheel. When the pressure on the steering wheel is removed, the control valves close and the actuator is inoperative. A supporting device constituting a separate subassembly. The control valve is connected to the actuator cylinder, when turning the steering wheel, it opens the supply of oil to the cylinder on the corresponding side of the piston. The oil pressure exerted on the piston causes the piston to move in the cylinder cylinder and the pressure is transferred to the longitudinal rod, and this one of the carols transfers the pressure to the steering knuckle mechanism.

The principle of operation of the booster. In this system, the steering shaft consists of two parts connected by a flexible joint. The bottom of the shaft goes through: by the actuator control mechanism and is mounted in it. A gear wheel is mounted at the end of the lower part of the shaft, meshed with the gear driving the globoid worm of the steering mechanism. The worm meshes with the roller mounted on the transverse shaft, at the end of which there is a lever, coupled with a hydraulic cylinder. The pump which maintains the oil operating pressure in the drive system is jointly with the generator. When turning the steering wheel, the corresponding valves in the steering mechanism are opened and oil is supplied to the hydraulic cylinder, which increases the pressure on the longitudinal bar. As already mentioned, the booster only then works, when the driver turns the steering wheel. When the pressure on the steering wheel is removed, the control valves close and the actuator is inoperative. A supporting device constituting a separate subassembly. The control valve is connected to the actuator cylinder, when turning the steering wheel, it opens the supply of oil to the cylinder on the corresponding side of the piston. The oil pressure exerted on the piston causes the piston to move in the cylinder cylinder and the pressure is transferred to the longitudinal rod, and this one of the carols transfers the pressure to the steering knuckle mechanism.