Start the engine and wait, until the radiator fan starts (this means that the operating temperature has been reached). Check short circuit angle and spark advance and adjust if necessary. The rest of the steps depend on the type of carburetor.

Weber ICEV or Solex DIS A (engines 900 and 1100)

■ Connect the tachometer and exhaust gas analyzer, start the engine.

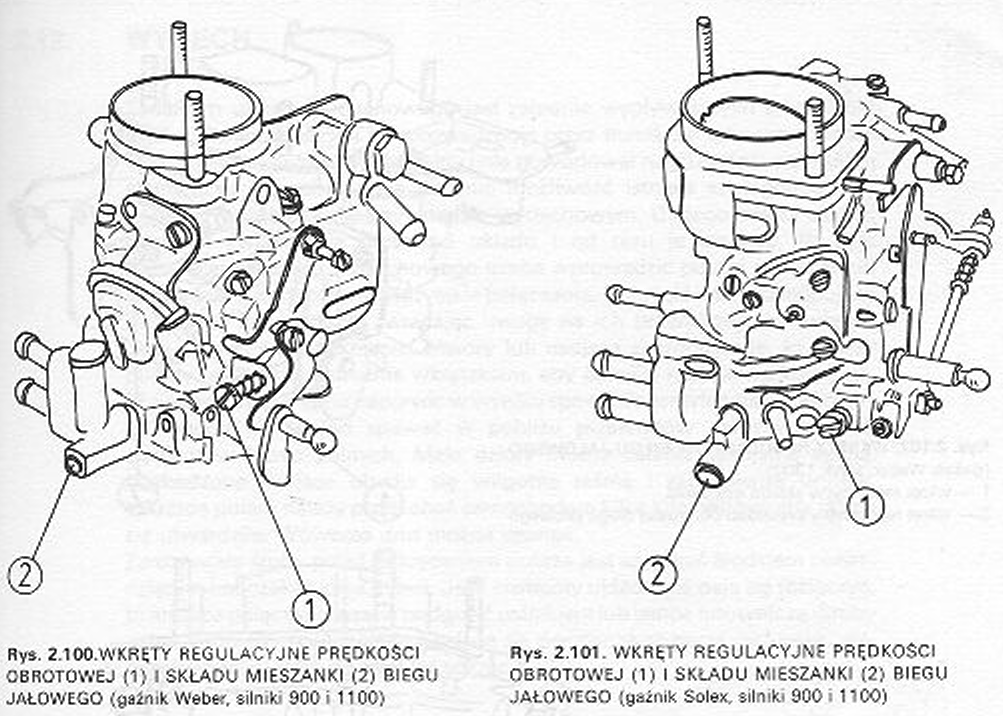

■ Remove the protection of the regulatory screw of the mixture composition (2, Lynx. 2.100 or 2.101).

■ Adjustment screw (1) set idle speed to 850 ± 50 rpm.

■ Operate the mixture adjustment screw for as long as possible (2), until the speed will stop increasing and the motor will run smoothly (CO concentration – about 3%).

■ Rotating the two adjustment screws alternately, set the required idle parameters (850 ± 50 rpm, CO 3± 0,5%).

■ Screw (2) secure with a new cap.

Weber DMTR or Solex CIC (engine 1300)

These types of carburetors have a factory-sealed mixture adjustment screw and only the idle screw is used to set the idle speed. (2). Using this screw, set the idle speed to 850 ± 50 rpm. If fine adjustment of the idle speed is required, you must have an exhaust gas analyzer. The CO concentration should be 2…3% by volume.

Idle adjustment method

■ Screw (2) set idle speed to 850 rpm.

■ Rotate the screw for so long (1), until the engine is at its highest speed.

■ If the engine speed has changed after this adjustment, it should be corrected with a screw (2), that is, to repeat both previous steps for so long, until the required value is reached.

The engine must run smoothly. The composition of the mixture is adjusted with a screw (1). screwing it in (depletion of the mixture and reduction of the share of CO) or by twisting (enriching the mixture and increasing the share of CO).