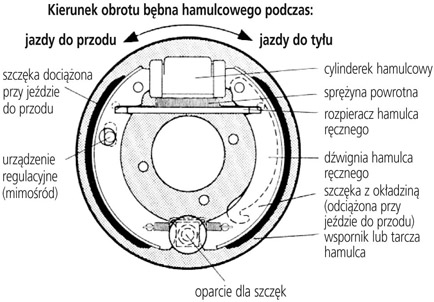

The disc brake mechanism is foldable: from the brake disc, which in the service brake is related to the wheel hub and in time (driving pivots in between, stirrup arms, and in the auxiliary brake it is mounted on the main shaft and while driving it rotates between two jaws; a stirrup that covers the brake disc with its arms; cylinders with pistons or jaws covered with friction lining and levers and tie rods or hydraulic lines. You have to remember, that regardless of the brake actuating system, the principle of their operation is always based on pressing the friction linings against the working surface of the drum. In most cars, the main brake is a drum brake with an inner working surface of the drum. Brake shoe systems. The braking force in each brake mechanism depends on the coefficient of friction between the linings of the shoes and the working surface of the brake drum, and on the degree of pressure of the shoes against the drum.. In the drum brake mechanism of the simplest design, in which two jaws are mounted on two pins, the pressure of the jaws against the drum is unequal. Concurrent jaw (left) it is pressed more strongly against the drum than the counter-rotating jaw (laws). In order to ensure the evenest possible pressure of the jaws against the drum and even wear of the friction linings, it is usually, that the contact angles of the jaws with the drum are asymmetrical. The shares of the leading shoe and the counter-rotating shoe in generating the braking force depend on the value of the friction coefficient between the mating surfaces and the location of the jaw locating pin.. In a brake mechanism with two shoes suspended on two separate pins, the lining of the trailing shoe wears much faster than the lining of the relatively weakly pressed contra-rotating shoe. Equal wear of the jaws can be ensured by: increasing the active surface of the friction lining of the concurrent jaw (increasing the angle of contact); differentiation of the pressures exerted by the spreader - the counter-rotating jaw is subjected to a force greater than the co-rotating jaw; supplying the trailing jaw with a lining with correspondingly higher abrasion resistance than the lining of the contra-rotating jaw.

The disc brake mechanism is foldable: from the brake disc, which in the service brake is related to the wheel hub and in time (driving pivots in between, stirrup arms, and in the auxiliary brake it is mounted on the main shaft and while driving it rotates between two jaws; a stirrup that covers the brake disc with its arms; cylinders with pistons or jaws covered with friction lining and levers and tie rods or hydraulic lines. You have to remember, that regardless of the brake actuating system, the principle of their operation is always based on pressing the friction linings against the working surface of the drum. In most cars, the main brake is a drum brake with an inner working surface of the drum. Brake shoe systems. The braking force in each brake mechanism depends on the coefficient of friction between the linings of the shoes and the working surface of the brake drum, and on the degree of pressure of the shoes against the drum.. In the drum brake mechanism of the simplest design, in which two jaws are mounted on two pins, the pressure of the jaws against the drum is unequal. Concurrent jaw (left) it is pressed more strongly against the drum than the counter-rotating jaw (laws). In order to ensure the evenest possible pressure of the jaws against the drum and even wear of the friction linings, it is usually, that the contact angles of the jaws with the drum are asymmetrical. The shares of the leading shoe and the counter-rotating shoe in generating the braking force depend on the value of the friction coefficient between the mating surfaces and the location of the jaw locating pin.. In a brake mechanism with two shoes suspended on two separate pins, the lining of the trailing shoe wears much faster than the lining of the relatively weakly pressed contra-rotating shoe. Equal wear of the jaws can be ensured by: increasing the active surface of the friction lining of the concurrent jaw (increasing the angle of contact); differentiation of the pressures exerted by the spreader - the counter-rotating jaw is subjected to a force greater than the co-rotating jaw; supplying the trailing jaw with a lining with correspondingly higher abrasion resistance than the lining of the contra-rotating jaw.