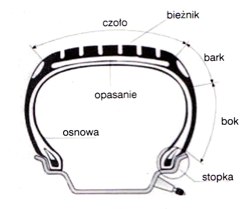

Construction of a tubeless car tire. A tubeless tire is basically the same structure as a tube tire, except that it is more flexible. In addition, it is lined with a layer of soft rubber inside, sealing the tire. In the case of e.g.. punctures of the tire with a nail, the inner elastic layer of rubber adheres closely to the nail and prevents air from entering the tire. You can recognize a tubeless tire by this, that the air valve is screwed directly onto the rim of the wheel. The size of modern tires is defined by two numbers: the first is the width of the tire, the other is the inner diameter of the tire, Corresponding to the outer diameter of the rim of the tire in contact with the rim of the bead. These dimensions are usually given in English inches (1 cal = 25,4 Mm). By marking the tire with low pressure, the width of the tire is given first, on the second there is a minus sign for, that they are low pressure tires, and in third place – rim diameter, e.g.. 4.50-16. The dimensions of the high-pressure tires first indicate the outer diameter of the tire as an integer (e.g. 34), on the second multiplication sign, and in the third, the width of the tire as an integer or with a fraction of the tire, e.g. 34X7 1/2 or 40X8 etc..

Construction of a tubeless car tire. A tubeless tire is basically the same structure as a tube tire, except that it is more flexible. In addition, it is lined with a layer of soft rubber inside, sealing the tire. In the case of e.g.. punctures of the tire with a nail, the inner elastic layer of rubber adheres closely to the nail and prevents air from entering the tire. You can recognize a tubeless tire by this, that the air valve is screwed directly onto the rim of the wheel. The size of modern tires is defined by two numbers: the first is the width of the tire, the other is the inner diameter of the tire, Corresponding to the outer diameter of the rim of the tire in contact with the rim of the bead. These dimensions are usually given in English inches (1 cal = 25,4 Mm). By marking the tire with low pressure, the width of the tire is given first, on the second there is a minus sign for, that they are low pressure tires, and in third place – rim diameter, e.g.. 4.50-16. The dimensions of the high-pressure tires first indicate the outer diameter of the tire as an integer (e.g. 34), on the second multiplication sign, and in the third, the width of the tire as an integer or with a fraction of the tire, e.g. 34X7 1/2 or 40X8 etc..